description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

Description

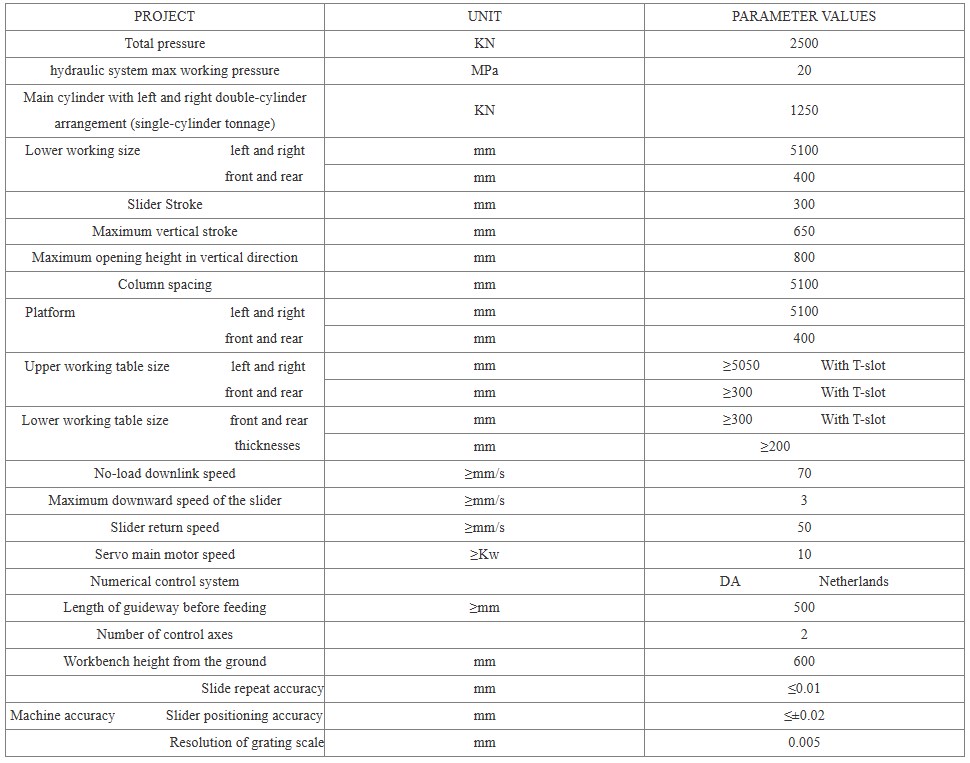

1、The model is advanced and beautiful. The two cylinders are fixed in the left and right columns. The stress state of the whole machine is reasonable and the rigidity is sufficient.

2、The electro-hydraulic servo synchronization method is used to ensure the synchronization of the oil cylinder. The synchronization performance is good, the anti-bias load capacity is strong, and the debugging is simple. The two oil cylinder stroke Y1 and Y2 are controlled separately, and two grating ruler are used to detect the displacement of the slider. The positioning accuracy can reach 0.02 mm, and the repeated positioning accuracy is 0.01 mm.

3、The X-axis of the rear block material is a ball screw pair, a linear guide and a synchronous pulley transmission mode, driven by an AC servo motor. The X-axis positioning accuracy can reach 0.05 mm, and the repeated positioning accuracy is 0.03 mm.

4、The electro-hydraulic servo control system is the Dutch Delem DA CNC system.

Parameters

.jpeg?x-oss-process=image/resize)