TSPA-5T MEA Servo-electric Hot Press Former

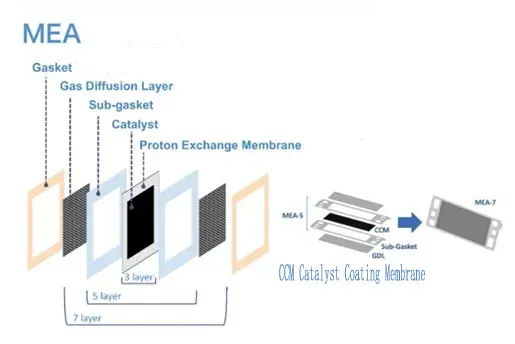

This series of equipment are mainly applied to materials processing and precise hot form compounding,such as MEA,transfer printing,composites,phenolic resin,high-precision mould pressing products which run with stable capability and high efficiency.

● Precision machining frame.

● Precision parallelism ±0.02mm, flatness ±0.02mm.

● Section-compartmentalized heating, temperature control uniformity±0.02; control accuracy rate 1%

● The accuracy of stroke control is high, and the repetitive precision is controlled in 0.1mm.

● Extremely low levels of noise and vibration.

● Hydraulic system equipped with fault monitoring device.

● PLC control system with digital display.

● High operating temperature.

We have many years of experience on study and design the technique of the MEA Servo-electric hot forming press, optimize the manufacture technology about the production of MEA hot-press forming. These hot-press forming machinerise have high precision machining frame, high quality; small deformation is small and stable performance.

Our MEA Servo-electric hot forming press can be used for thermal compound between films, and fuel cell MEA six-in-one thermal compounding technology, which is very suitable for a wide range of producing, Servo-electric hot forming press can mold the machine parts in smaller tonnage. This type of hot forming press generally considered more efficient and better at forming complex parts.

The MEA Servo-electric hot forming press has a very superlative control system that provides the operator with complete control, easy use and accurate performance. MEA Servo-electric hot forming press can also be equipped with low temperature pressing procedure. With our expertise, we can provide advise for our customers to use the auxiliary equipment of our MEA Servo-electric hot forming press to improve performance, speed and efficiency.

The MEA Servo-electric hot forming press use high temperatures to help form the workpiece so that require less capacity to form the product. Typical tonnage of this machines is between 1-20T, also customer specification are available for larger equipment upon request.

|

No. |

Item |

Unit |

Data |

|||||

|

1 |

Nominal Pressure |

KN |

20 |

50 |

100 |

200 |

||

|

2 |

Distance between Upper&Lower Platform |

mm |

300 |

|||||

|

3 |

Max Stroke of Cylinder |

mm |

300 |

|||||

|

4 |

Available Size of Platform |

Left& |

mm |

300 |

400 |

500 |

550 |

|

|

|

|

Front& |

mm |

300 |

400 |

500 |

550 |

|

|

5 |

Running Speed of Platform |

Fast Running Downwards |

mm/s |

1-40 |

||||

|

|

|

Slow Running Downwards |

mm/s |

0.01-3 |

||||

|

|

|

Return Stroke |

mm/s |

1-40 |

||||

|

6 |

Parallelism Degree of Upper&lower Platform |

mm |

±0.02 |

|||||

|

7 |

Working Platform Flatness |

mm |

±0.02 |

|||||

|

8 |

Pressure control Precision |

KN |

±1% |

|||||

|

9 |

Max Temperature of Hot Plate |

℃ |

250 |

|||||

|

10 |

Heating Rate(Controllable) |

℃/min |

1-6 |

|||||

|

11 |

|

Pressure Gradient |

KN |

9 |

||||

|

12 |

Temp Gradient |

℃ |

9 |

|||||

|

13 |

Time Gradient |

S |

9 |

|||||

|

14 |

Temp Display Control Precision |

℃ |

±0.5 |

|||||

|

15 |

Hot Plate Flat Temp Error |

℃ |

±2 |

|||||

|

16 |

Equipment Pressure Maintaining & Drop |

MPa |

≤1/2 |

|||||

|

17 |

Motor Power(approximate) |

KW |

Adjusting the power of motor in accordance with the speed 1-15KW |

|||||

|

18 |

Heating Power |

KW |

10 |

15 |

20 |

25 |

||

|

19 |

Distance between Lower Hot plate and ground |

mm |

≤750 |

800 |

||||

|

20 |

Total Weight |

KG |

≦1000 |

2000 |

3000 |

4000 |

||

Applied to fuel cell MEA hot pressing form、high temperature molding press for the composite materials、automobile parts、mold parts、cold/hot forming and error correction. It can also be applied to produce complex components and other industrial components.

.webp)

The above information is the main frame ,features and parameters of our typical MEA electric-servo hot former.It contains two types,i.e. electric-servo hot former and electric-servo cold former,which can be customized at your option.

.jpeg?x-oss-process=image/resize)

.png?x-oss-process=image/resize,w_100/quality,q_100)