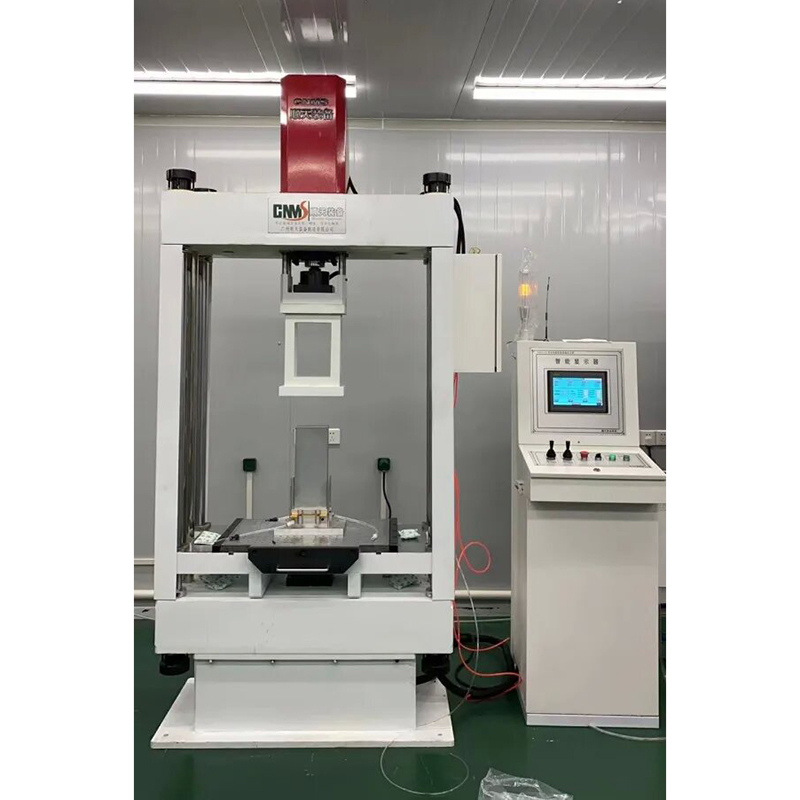

Fuel Cell Stack Assembly Electric Servo Press

Mainly used for the assembly of fuel cell stacks and tightness detection.

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

Description

Fuel cell stack assembly electric servo press is designed specifically for hydrogen fuel cell stack assembly of special equipment, with decades of accumulated experience, combined with the installation of hydrogen fuel cell technology, the use of specially designed fixtures, bipolar plate membrane electrodes, end plate, collector plate, the whole batch of gas tightness testing production.

Double-action electric stack assembly servo press is composed of synchronized upper and lower electric cylinders.

1. The equipment adopts four-column structure servo motor driven ball screw movement, smart display or IPC for display.

2. Real-time press fitting curve display and storage function, realizing 0% of NG products.

3. High precision displacement and pressure,the repetition accuracy can reach 0.01 mm.

4. Multiple sets of press-fitting programs can be set to realize multi-purpose use of one machine.

5. Energy-saving effect of more than 99%, and more environmental protection, safe, can meet the requirements of the use of equipment in the clean room.

6. The running way of the equipment is as follows: fast forward, detection, press fitting, buffer, pressure preservation and return.

Equipment features

The pressing of the left and right head is stable, and the accuracy of parallelism and flatness is highlt has the function of storage and step less speed regulation in the process of process form ula parameters.The servo lifting platform has the advantages of stable and reliable lifting, accurate tilt lifting angle, reliable lockingsafety and strong stability, double-action piezoelectric stack using electric cylinder, high precision positioning,stable movement, uniform and reliable force, convenient operation and stable performance.Ihe equipment is designed in accordance with the corresponding international standards or industry standards,the structure has enough static, dynamic, thermal nigidity and precision, safety and environmental protectionmeet the national standards.

Ihe control system is advanced, the system components have high precision, good reliability, strong anti-inter-ference ability and fast response speed of the servo system.The operation and maintenance of the equipment is simple and convenient, and the after-sales service isexcellent.

Technical parameters

|

Model

Parameters

|

Unit

|

TSPD-2T

|

TSPD-3T

|

TSPD-5T

|

TSPD-10T

|

TSPD-20T

|

|

|

Maximum nominal force

|

KN

|

20

|

30

|

50

|

100

|

200

|

|

|

Maximum Compression force

|

KN

|

20

|

30

|

50

|

100

|

200

|

|

|

Maximum stroke of electeic cylinder

|

mm

|

300

|

400

|

500

|

600

|

600

|

|

|

Error of working pressure

|

MPa

|

≤0.1%

|

≤0.1%

|

≤0.1%

|

≤0.1%

|

≤0.1%

|

|

|

Maximum stroke of electeic cylinder

|

mm

|

300

|

400

|

400

|

500

|

600

|

|

|

Maximum opening distance between the left and right indenter

|

mm

|

500

|

600

|

800

|

800

|

1000

|

|

|

Effective dimensions of upper indenter

|

L

|

mm

|

250

|

300

|

350

|

350

|

400

|

|

W

|

mm

|

80

|

80

|

90

|

90

|

100

|

|

|

Maximum size of lower workbench

|

L

|

mm

|

500

|

600

|

600

|

700

|

800

|

|

W

|

mm

|

200

|

200

|

300

|

300

|

300

|

|

|

Flatness of working table

|

mm

|

≤±0.015

|

≤±0.015

|

≤±0.015

|

≤±0.015

|

≤±0.015

|

|

|

worktable parallelism

|

mm

|

≤±0.02

|

≤±0.02

|

≤±0.02

|

≤±0.02

|

≤±0.02

|

|

|

Pressure precision control

|

Error rating

|

MPa

|

≤±0.01

|

≤±0.01

|

≤±0.01

|

≤±0.01

|

≤±0.01

|

|

Compressing speed and travelling speed

(Can be setting the range)

|

Quick compaction

|

mm/s

|

0-60

|

0-60

|

0-60

|

0-60

|

0-60

|

|

Press down slowly

|

mm/s

|

0.01-3

|

0.01-3

|

0.01-3

|

0.01-3

|

0.01-3

|

|

|

back swing

|

mm/s

|

0-60

|

0-60

|

0-60

|

0-60

|

0-60

|

|

|

Hydraulic cushion speed

|

Lifting Speed

|

mm/s

|

0.01-1

|

0.01-1

|

0.01-1

|

0.01-1

|

0.01-1

|

|

Lifting Distance of floating platform

|

mm

|

40

|

40

|

60

|

60

|

60

|

|

|

Power of main servo motor

|

KW

|

1.5

|

2

|

2

|

3

|

5

|

|

|

Dimensions

|

Depends on products

|

||||||

|

Installation stack holding effective size

|

Can be customized

|

||||||

|

Total weight of the machine

|

≤1000

|

≤1500

|

≤2000

|

≤3000

|

≤3500

|

||

.jpeg?x-oss-process=image/resize)

.png?x-oss-process=image/resize,w_100/quality,q_100)